Relocating a warehouse is one of the most complex projects a business can undertake. Unlike standard office or retail moves, a warehouse relocation involves heavy machinery, industrial equipment, palletized inventory, sensitive stock, racking systems, forklifts, and critical logistics planning. If you’re preparing for warehouse relocation in Richmond, you already know how important it is to minimize downtime, protect valuable inventory, and ensure a safe, efficient transition.

At Richmond Moving Company, our team handles small to large-scale commercial and industrial relocations across Richmond, Vancouver, Burnaby, Delta, New Westminster, and Surrey. With years of hands-on experience moving factories, warehouses, storage facilities, and logistics centres, we understand the level of precision required for a successful warehouse transition.

In this comprehensive guide, we’ll walk you through every step of the warehouse relocation process, including planning, inventory preparation, equipment handling, logistics, safety requirements, and how to select the right warehouse movers in Richmond.

Why Warehouse Relocation Requires Professional Expertise

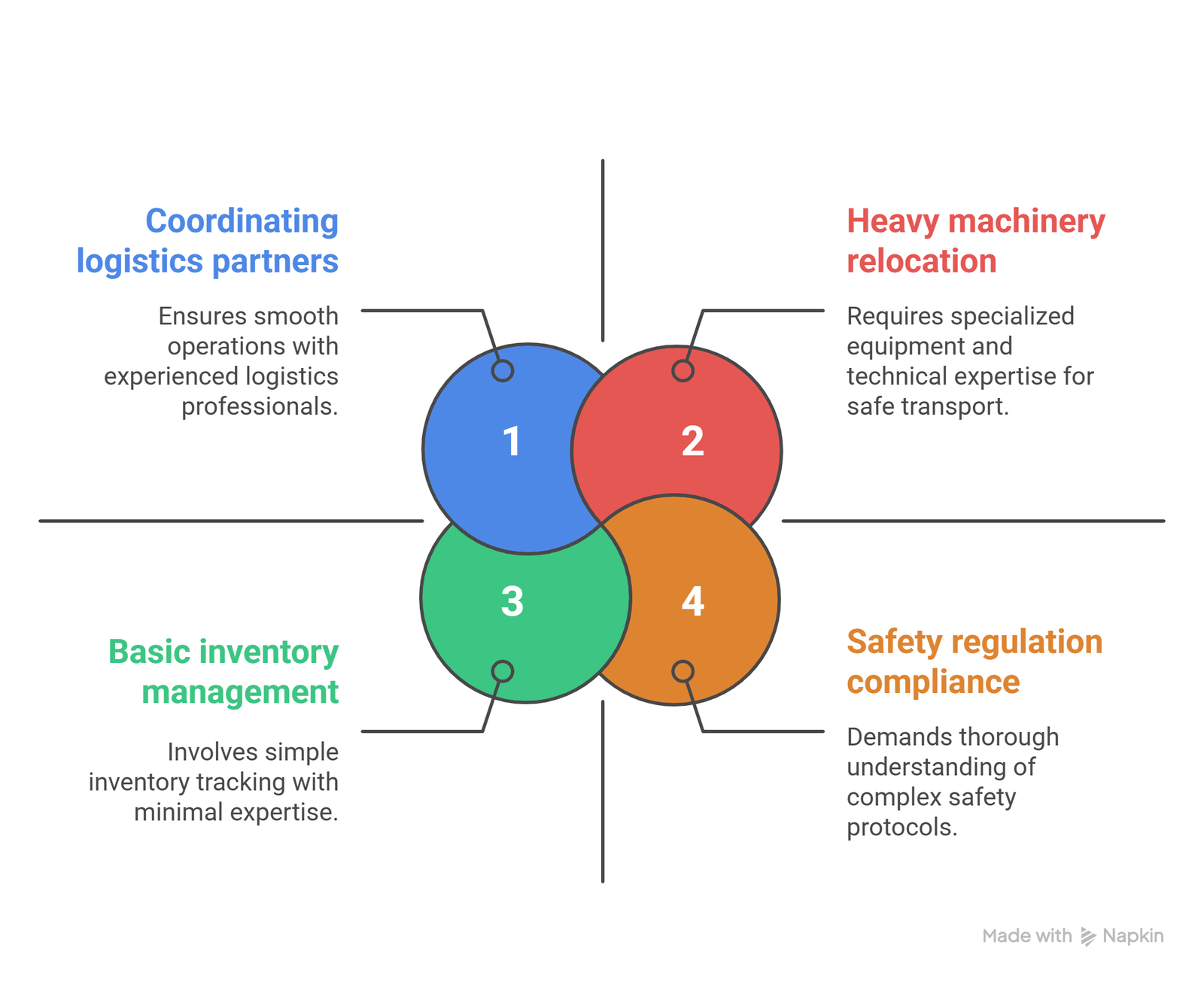

Warehouse moves involve significantly more complexity than standard commercial or office relocation. Businesses often face challenges such as:

-

Heavy machinery and industrial equipment

-

Large pallet racks and shelving

-

High-volume inventory

-

Dock equipment and forklifts

-

Safety regulations and hazard protocols

-

Avoiding operational downtime

-

Coordinating with vendors, suppliers, and logistics partners

That’s why hiring experienced industrial movers in Richmond BC becomes essential. Professionals bring specialized equipment, technical expertise, and trained crews who understand how to dismantle, move, transport, and re-install warehouse systems securely.

If your business wants to avoid delays, accidents, and costly downtime, having the right team behind you makes all the difference.

Step 1: Conduct a Full Warehouse Assessment

A successful warehouse relocation begins with a detailed assessment of:

✔ Inventory volume and categories

✔ Machinery, equipment, and tools

✔ Racking systems and shelving

✔ Electrical, plumbing, and HVAC connections

✔ Safety hazards and operational risks

✔ Dock configuration and loading space

This stage ensures nothing is overlooked. At Richmond Moving Company, we create a full warehouse moving checklist outlining your current layout, inventory structure, and operational requirements for the new facility.

Step 2: Establish a Detailed Warehouse Transition Plan

Every smooth warehouse relocation requires an organized plan. This usually includes:

1. Timeline planning

Determine ideal moving dates, peak season schedules, employee shifts, and operational slow periods.

2. Assigning responsibilities

Employees, supervisors, and your chosen movers must understand their roles.

3. Labeling and inventory guidelines

Clear labels ensure stock and equipment reach the correct zones in your new warehouse.

4. Vendor/supplier communication

Let logistics partners know about your relocation to avoid shipment confusion.

A well-structured transition plan reduces the risk of miscommunication, downtime, and lost inventory during the move.

Step 3: Prepare Inventory and Pallet Systems

Inventory preparation is a core step in any warehouse relocation. To ensure everything moves seamlessly:

✔ Audit your current inventory

Identify slow-moving, obsolete, or damaged items.

✔ Categorize stock

Separate inventory by zone, product type, or distribution flow.

✔ Pack and palletize

Use durable pallets, shrink wrap, and protective coverings.

✔ Remove hazardous materials

Certain chemicals or industrial supplies must follow safety protocols.

As professional Richmond warehouse movers, we handle pallet and inventory moving services using lift equipment, pallet jacks, and secure transportation methods to prevent damage.

Step 4: Dismantle Racking, Shelving & Bulk Storage Systems

Industrial racking systems require special tools and trained technicians for safe dismantling. Incorrect handling can damage structural components and create safety risks.

Our team ensures:

-

Boltless racks are carefully disassembled

-

Pallet racks are labelled for easy reassembly

-

Shelves, mezzanines, and platforms are securely wrapped

-

All components are organized for efficient installation at the new site

Professional handling ensures your racking systems are ready for fast re-installation—minimizing downtime.

Step 5: Moving Heavy Equipment, Machinery & Forklifts

This is where most warehouse relocations go wrong—unless you have trained industrial movers in Richmond BC. Moving heavy equipment requires:

✔ Specialized dollies

✔ Forklifts and lift trucks

✔ Crating and rigging

✔ Safety-certified movers

✔ Proper weight distribution planning

We relocate:

-

Conveyor systems

-

Industrial machinery

-

Pallet wrappers

-

Forklifts

-

Dock equipment

-

Loading machinery

-

Assembly-line components

Our crew ensures all equipment is properly secured, disconnected, and safely transported according to BC safety regulations.

Step 6: Transportation and Logistics Coordination

Efficient transportation is essential for reducing downtime and maintaining productivity. During warehouse relocation, we handle:

-

Route planning

-

Fleet coordination

-

Loading/unloading timelines

-

Parking and access approvals

-

Weather-related logistics

-

Secure transportation of high-value items

Our logistics team ensures your warehouse transition is smooth and on schedule, with detailed communication at every stage.

Step 7: Reassembly, Setup & New Warehouse Configuration

Once your assets reach the new warehouse, our team re-installs:

✔ Racking systems

✔ Pallet shelving

✔ Warehouse stations

✔ Bulk storage units

✔ Machinery and equipment

We follow your warehouse layout plan or help design an optimized version to improve workflow and operational efficiency.

This includes establishing:

-

Receiving zones

-

Packing & staging areas

-

Inventory aisles

-

Safety aisles

-

Forklift routes

A professionally organized setup helps businesses return to operations faster.

Step 8: Final Inspection & Post-Move Optimization

After the warehouse move is complete, businesses should:

✔ Perform an inventory accuracy check

✔ Ensure equipment is functioning properly

✔ Verify racking stability and alignment

✔ Inspect for safety hazards

✔ Confirm all items are accounted for

Richmond Moving Company also provides post-relocation support to ensure your operations resume smoothly.

Warehouse Relocation Cost Breakdown

Costs vary depending on warehouse size, equipment, inventory volume, and distance. Below is a sample overview:

| Warehouse Size / Task | Estimated Cost Range |

|---|---|

| Small Warehouse (under 5,000 sq ft) | $3,500 – $8,000 |

| Medium Warehouse (5,000–20,000 sq ft) | $8,000 – $20,000 |

| Large Warehouse (20,000–50,000 sq ft) | $20,000 – $50,000+ |

| Heavy Equipment Moving | $150 – $400 per unit |

| Racking Dismantle & Reinstall | $2,000 – $10,000 |

| Pallet & Inventory Moving | $800 – $4,000 |

(These are general industry estimates; contact us for an accurate quote.)

Why Choose Richmond Moving Company for Warehouse Relocation?

Richmond Moving Company is one of the few movers in BC specializing in commercial warehouse relocation, industrial moving, and factory moves. Our strong reputation comes from:

✔ Licensed, insured, and certified industrial movers

✔ Specialized equipment for heavy and high-volume moves

✔ Experienced technicians for dismantling/reinstalling racking

✔ Transparent pricing and detailed planning

✔ Minimal downtime strategies

✔ Local service coverage across Richmond, Vancouver, Burnaby, Delta, Surrey & New Westminster

We understand the pressure businesses face during relocation—and our goal is always to deliver seamless moves with zero compromise on safety or efficiency.

Frequently Asked Questions (FAQs)

1. How long does a warehouse relocation in Richmond usually take?

Most warehouse moves take anywhere from 2 days to 2 weeks, depending on size, equipment, and inventory volume. Larger facilities require more planning and staging.

2. How do I reduce downtime during a warehouse move?

Plan early, categorize inventory, schedule moves during off-peak hours, and hire professional Richmond warehouse movers who offer detailed transition planning.

3. Can heavy machinery be moved safely?

Yes — with trained industrial movers, proper rigging tools, and certified equipment, heavy machinery can be relocated safely and efficiently.

4. Do you offer dismantling and reassembly of pallet racking?

Absolutely. Our technicians dismantle, label, transport, and reinstall racking systems with full structural safety checks.

5. How far in advance should I schedule a warehouse relocation?

Most businesses schedule 6–12 weeks in advance to allow time for planning, layout design, and inventory preparation.

Strong Call-to-Action (CTA)

If you’re planning a warehouse relocation in Richmond, don’t leave it to chance. Trust the professionals who understand commercial logistics, heavy equipment handling, and downtime reduction.

📞 Call Richmond Moving Company today: +1 (604) 330-5130

📩 Request a free quote: https://richmondmovingcompany.ca/contact/

🌐 Explore all services: https://richmondmovingcompany.ca/services/

Move your warehouse with confidence — the right team makes all the difference.